The Challenge: Frequent Wear and High Maintenance Costs

A Victorian construction materials supplier struggled with excessive wear on the Remaline 40 orange rubber lining at the head discharge of their conveyor. Handling washed sand with large lump sizes caused rapid wear, requiring replacements every 3-4 months, leading to high maintenance costs and downtime.

The Solution: A Durable Polyurethane Upgrade – K-Redi-Liner®

Following a conveyor health check, the customer trialed Kinder’s K-Redi-Liner® Polyurethane G83 in their head chute. This high-impact, high-abrasion-resistant liner offered:

- Extended Wear Life: Outlasts rubber linings, reducing replacement frequency.

- Even Wear Distribution: Rotational capability maximises lifespan.

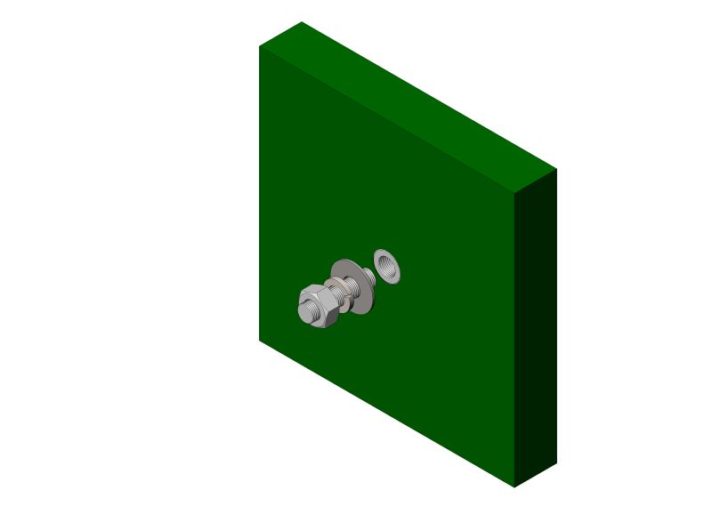

- Easy Installation: Lightweight 2×2 panels with a single-bolting system.

To enhance protection, the liner was installed throughout the lower chute as well.

The Results: Zero Replacements, Minimal Wear

Since July 2024, the customer has reported zero replacements and maintenance needs. Even after 8 months of operation, wear is minimal, significantly reducing downtime. Impressed by the results, they have installed K-Redi-Liner® Polyurethane in four additional chutes.

“Previously, we replaced rubber lining every 3-4 months. Since installing K-Redi-Liner®, we haven’t needed any replacements or maintenance. Even after 10 months, wear is minimal, and downtime has been eliminated.”, Maintenance teams reported.

By choosing K-Redi-Liner® Polyurethane G83, the operator has enhanced durability, reduced costs, and improved productivity. If frequent wear and costly downtime are challenges, Kinder’s innovative wear solutions could be the answer.